AM-ACTS Objectives

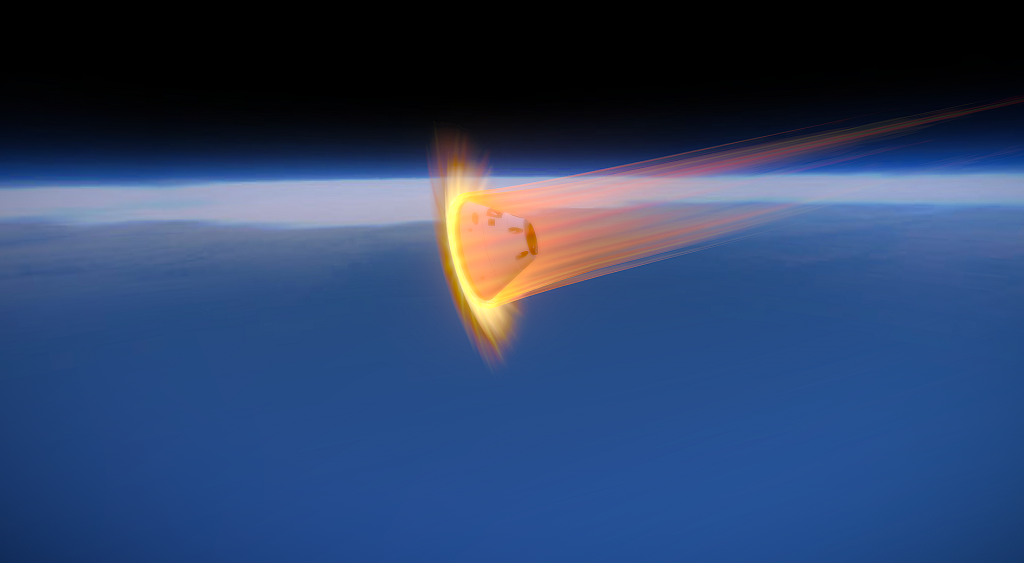

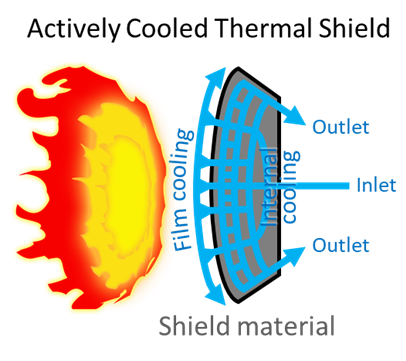

In line with the goals of both M-ERA.Net and Horizon Europe Work Strategic Plan 2021-2024, the main objective of AM-ACTS project is to develop novel high-performance Actively Cooled Thermal Shields (ACTS) through additive manufacturing of lightweight microchanneled parts from ultra-high temperature ceramics (UHTCs) and/or refractory metals which could be used, for example, in atmospheric re-entry shields, turbine blades, rocket engines, reactor walls or solar receivers with improved maximum service temperature and/or service lifetime at a given operating temperature over current passive thermal protection systems (TPS), which could boost the efficiency and reduce maintenance costs in these and many other industrial applications.

This will be achieved through a reduction of the internal temperatures of the system by circulating coolant through a bioinspired internal microchannel network similar to those used by animal and plants for thermoregulation. Reduction of external surface temperature in Actively Cooled Thermal Shields (ACTS) would also be sought through the formation of a protective gas thin film using transpiration cooling. Lowering material temperature will reduce oxidation/corrosion and transpiration cooling will also mitigate ablation of the external surface. Development of optimal microchannel network design will be performed with the aid of computational fluid dynamics (CFD). Optimal coolant and flow rates for both closed-loop and transpiration cooling systems will be identified.

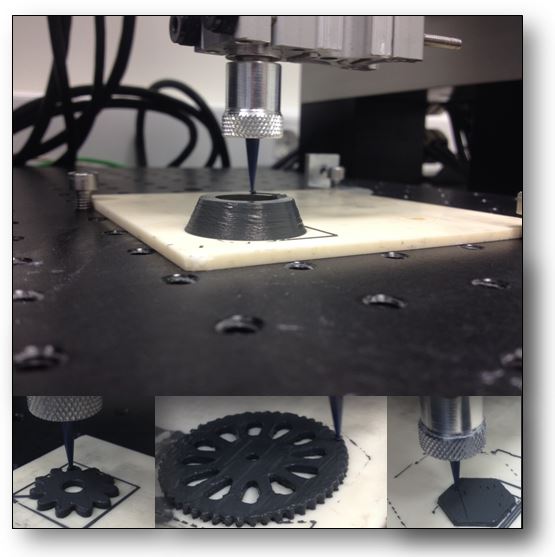

- UHTCs and refractory alloys-based feedstock materials for AM processes (DIW, DLP, DED, etc.) will be developed for fabrication of microchanneled parts.

- ACTS developed in this project will require smaller thicknesses to reduce the internal temperature to the required operating levels and be more lightweight since part of the required volume will be occupied by the microchannel network.

- An optimal compromise between weight and volume savings and coolant flow requirements will be sought since the weight/volume of the coolant and cooling system itself must be considered.

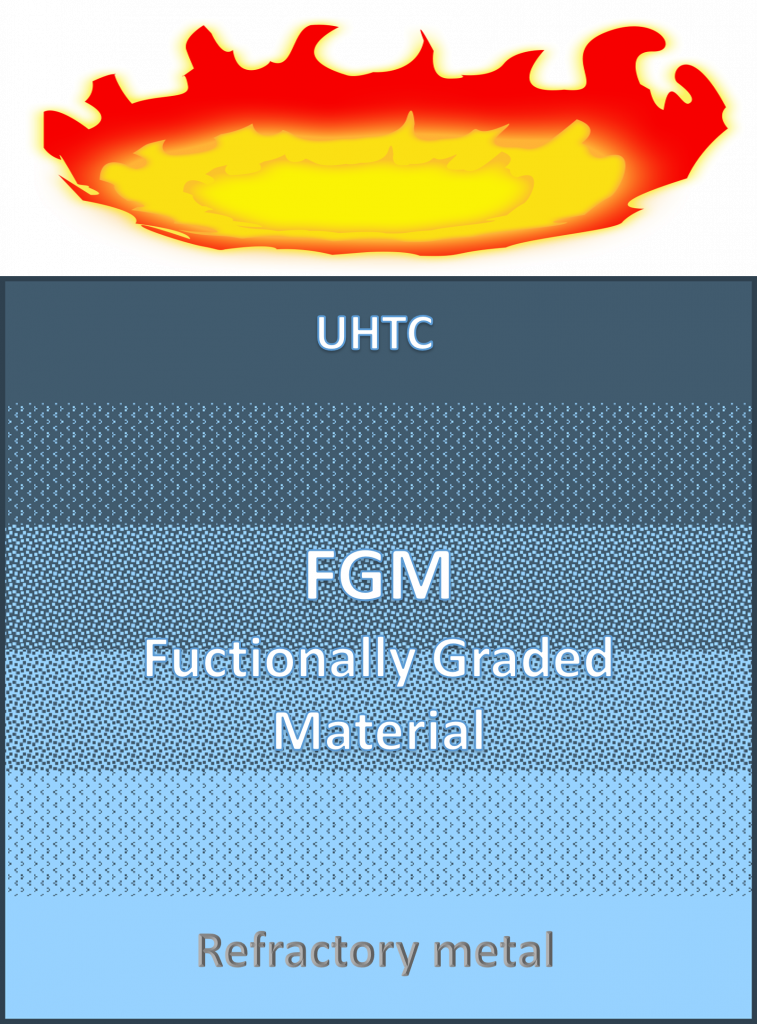

- Material composition in UHTCs will be optimized (e.g., through addition of reinforcements) to further minimize oxidation and maximize mechanical strength and toughness.

- ACTS designs with Functionaly Graded Material (FGM) structure combining UHTCs and refractory alloys will be developed by AM, trying to efficiently combine the advantages in terms of oxidation, mechanical and thermal properties of both groups of materials.

- An optimal compromise between weight and volume savings and coolant flow requirements will be sought since the weight/volume of the coolant and cooling system itself must be considered.

- Effect of cooling on ablation and oxidation rates under re-entry simulated conditions on the ACTS systems will be evaluated and key strategies to minimize degradation will be identified.

As expected of any research project, the scientific results would be disseminated both within the scientific community as joint publications in internationally reputed journals, communications at scientific conferences and technological fairs, as well as to the broader public. Technological innovations resulting from the project would be protected and spread through companies and international and European networks in the field of materials, advance manufacturing, aerospace and energy, searching for additional strategic partners to further advance the ACTS concept after completion of the project, and for their ulterior commercial exploitation.